|

معلومات تفصيلية |

|||

| التكوين الكيميائي: | آل | مادة: | الألومنيوم |

|---|---|---|---|

| آل المحتوى: | سبائك الألومنيوم | نوع السبائك: | سبيكة الـ Al-Zn-In |

| محتوى الزنك: | 2.5-7.0% | في المحتوى: | 0.018-0.050% |

| محتوى القرص المضغوط: | 0.005-0.020% | محتوى sn: | 0.018-0.075% |

| محتوى المغنيسيوم: | 0.50-1.50% | محتوى سي: | 0.10-0.15% |

| محتوى Ti: | 0.01-0.08٪ | جهد الدائرة المفتوحة: | -1.18 إلى -1.10 فولت |

| جهد الدائرة المغلقة: | -1.12 إلى -1.05 فولت | القدرة الفعلية: | ≥2400 أمبير/كجم |

| الكفاءة الحالية: | ≥85 ٪ | ||

| إبراز: | ISO9001:2008 Certified Sacrificial Aluminum Anode,GB/T 4948-2002 Standard Aluminum Bracelet Anode,Galvanic Corrosion Protection Aluminum Alloy Anode,GB/T 4948-2002 Standard Aluminum Bracelet Anode,Galvanic Corrosion Protection Aluminum Alloy Anode |

||

منتوج وصف

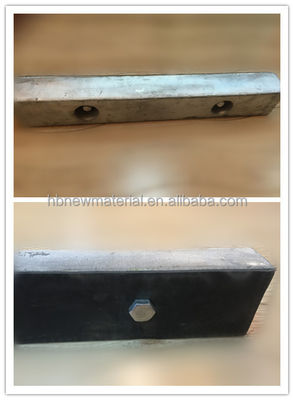

Sacrificial Aluminum Bracelet Anodes for Galvanic Corrosion

Sacrificial bracelet anodes are typically made from either zinc alloy or aluminum alloy, depending on design requirements, environmental variables, and water salinity. These anodes provide cost-effective and reliable cathodic protection for submerged pipelines, which are usually coated with anti-corrosion materials and weighted with concrete for negative buoyancy.

Bracelet anodes are mounted at specific locations determined by the cathodic protection system design and are electrically connected to the pipeline via special bonding copper cables. While the primary defense against corrosion is the pipeline's anti-corrosion coating, bracelet anodes protect areas where coating failures may occur during installation or operation.

Applications

These anodes are used for:

- Hull protection

- Ballast tanks

- Offshore engineering

- Harbor structures

- Sea water cooling systems

- Submerged pipelines

Chemical Composition Standards

| Type | Zn | In | Cd | Sn | Mg | Si | Ti | Impurity (less than) | Al |

|---|---|---|---|---|---|---|---|---|---|

| Al-Zn-In-Cd A11 | 2.5-4.5 | 0.018-0.050 | 0.005-0.020 | - | - | -- | - | 0.10 | Balance |

| Al-Zn-In-Sn A12 | 2.2-5.2 | 0.020-0.045 | - | 0.018-0.035 | - | - | - | 0.10 | Balance |

| Al-Zn-In-Si A13 | 5.5-7.0 | 0.025-0.035 | - | - | - | 0.10-0.15 | - | 0.10 | Balance |

| Al-Zn-In-Sn-Mg A14 | 2.5-4.0 | 0.020-0.050 | - | 0.025-0.075 | 0.50-1.00 | - | - | 0.10 | Balance |

| Al-Zn-In-Mg-Ti A21 | 4.0-7.0 | 0.02-0.050 | - | - | 0.50-1.50 | - | 0.01-0.08 | 0.10 | Balance |

Electrochemical Characteristics

| Item | Material of anodes | Open-circuit Voltage (v) | Close-circuit Voltage (v) | Actual Capacity(Ah/kg) | Current efficiency (%) | Consumption rate (kg.(A.a)) | Dissolve Performance |

|---|---|---|---|---|---|---|---|

| Electrochemical Performance | Type 1 | -1.18- -1.10 | -1.12- -1.05 | ≥ 2400 | ≥ 85 | ≤ 3.65 | The surface dissolve evenly & oxide drop easily |

| Type 2 | -1.18- -1.10 | -1.12- -1.05 | ≥ 2600 | ≥ 90 | ≤ 3.37 |

Reference electrode: Saturated calomel electrode

Type 1: A11, A12, A13, A14

Type 2: A21

Type 1: A11, A12, A13, A14

Type 2: A21

Why Choose Us?

Q. Why choose us?

A. We have over 20 years of experience in the cathodic protection anode market. Our products are strictly produced and tested according to American standard ASTM G97, ensuring continuous and stable high quality that saves you costs.

B. We offer prompt shipment. For urgent needs, we maintain stock of regular shape anodes to enable quick delivery, even when standard plant delivery time is 20 days.

Company Culture

- Our Belief: Continuous Innovation

- Our Spirit: Sincerity, Unity, Dedicated, Hardworking

- Our Mission: Provide most advanced products & most professional technical solution

Certification

Inspection & Lab

تريد أن تعرف المزيد من التفاصيل حول هذا المنتج